Propeller Shaft Bearing Noise

Welcome to our site! Here we have a plenty of propeller shaft bearing noise for you as your basic idea in your next woodworking project. Feel free to download the image and use it as your guideline. However, the free propeller shaft bearing noise images provided below is not given in a detailed manner. You can only see the finished project's image which not include the step by step guide.Woodwork, even for a simple project like propeller shaft bearing noise need a precise measurement and guides. What you going to need are step by step details, plans, templates, cutting materials lists and many more.

Warning!!

Starting a woodworking project without proper guide increase the risk of financial loss due to wasted material used in failed projects.

If you are serious in starting your woodworking project, you should take a look at The Ted's Woodworking resources! It consist of 16,000 woodworking project with very detailed instruction even a beginner can understand.

The product will include step by step details, plans, templates, cutting materials lists and many more.

Click the banner below to find out more:

Drive shaft noises and possible causes are as follows.

Propeller shaft bearing noise. If the angle is more than this you may have trouble with vibration and premature joint wear. This reduces vibration and helps to protect against bending and vertical changes the manufacturer supplies over 90 oe quality propshaft centre bearings for a variety of vehicle makes and models. Grinding and squeaking from the drive shaft is frequently caused by worn universal joints. The angle should be in the range of three to eight degrees depending on shaft rpm.

I believe this noise which occurs between 30 40 mph is caused by a bad propeller shaft. A worn bearing will create a clicking or growling noise depending on how bad. Hey everyone got a question about the lower unit on my 1984 evinrude 70hp. It was the drive shaft bearing that caused the noise.

Its purpose is to serve as support for the vehicle s drive shaft and the metal shaft that goes along the underside of the vehicle and transfers power from the vehicle s transmission to the rear differential where it is then transferred to the wheels. He pointed out how important it was to get the driveshaft reassembled exactly in the same position as before to avoid vibrations due to imbalance. No water in the oil and it shifts and holds gear fine. The joints become dry causing the rollers to wear.

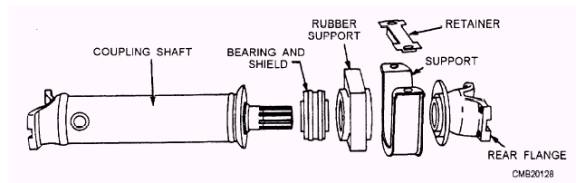

I have noticed that there appears to be a knocking noise coming from the lower unit area of the engine underway only. It is also important to measure the angle of a two piece shaft. The other way it can fail is the bearing can eventually wear out. The centre bearing keeps the shaft in the correct position and attaches it to the chassis or body via rubber and metal mountings.

Upon further inspection it looks like there is side to side play in the prop shaft not very much just enough to feel it but not really see it. It took my mechanic 6 hours to replace and that was mostly time for access. I believe this noise which occurs between 30 40 mph is caused by a bad propeller shaft center support bearing. The unlubricated damaged rollers then produce a grinding or squeaking sound as they operate on the scored cap and cross surfaces.